The Ultimate Guide to Choosing the Best Screw Second Punch for Your Needs

In today's fast-paced manufacturing environment, optimizing production efficiency and precision is paramount, making the selection of the appropriate tools critical. One such tool that has garnered attention is the Screw Second Punch. According to a report by IBISWorld, the global industrial tools market is projected to reach $120 billion by 2025, emphasizing the significance of specialized tools like the Screw Second Punch in increasing productivity and reducing downtime. In fact, industry studies suggest that the right choice of tooling can enhance operational efficiency by up to 30%. This guide aims to provide you with a comprehensive understanding of how to choose the best Screw Second Punch tailored to your specific needs, outlining key factors to consider, common pitfalls to avoid, and the remarkable benefits that come with making an informed selection.

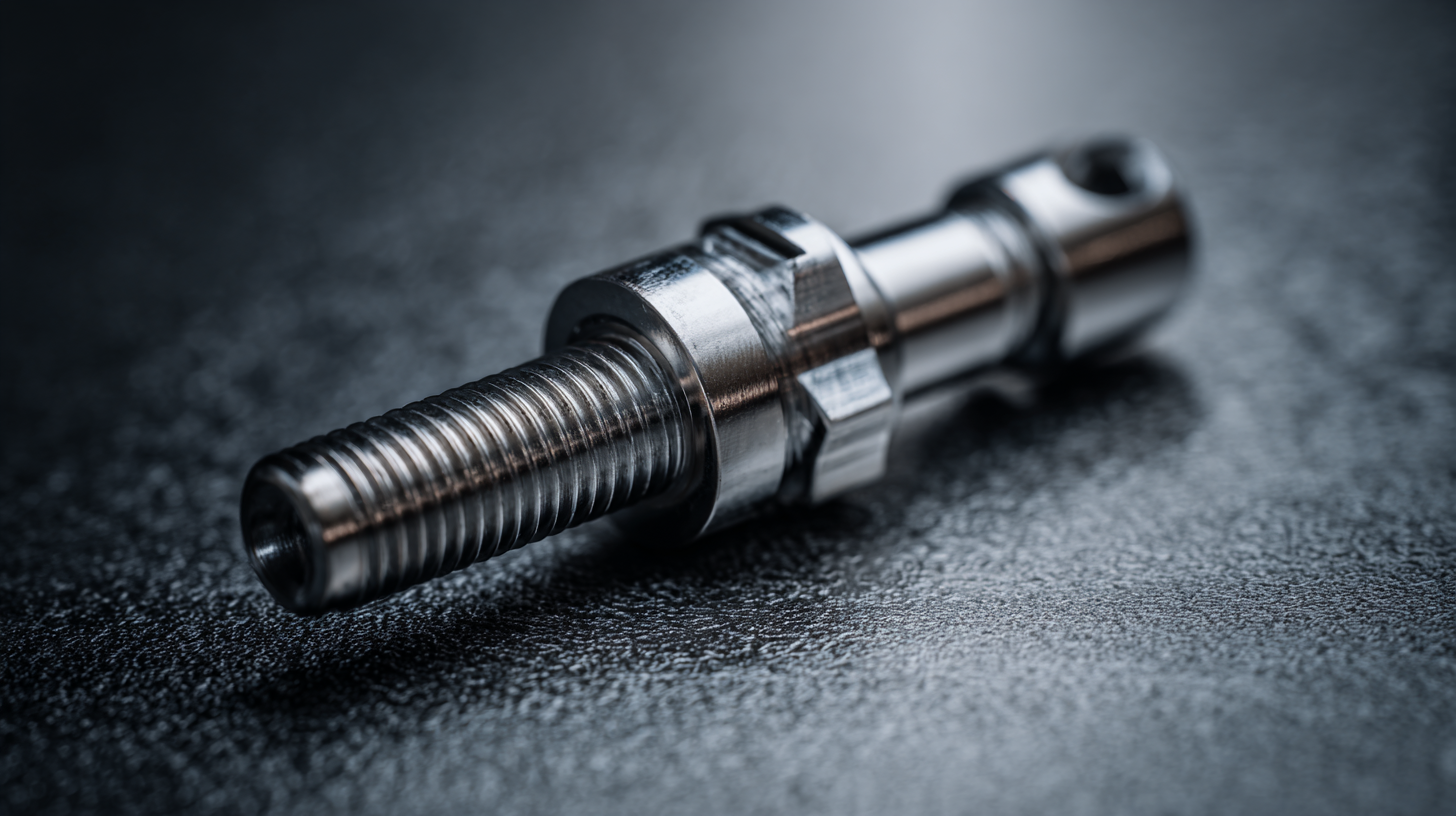

Understanding the Different Types of Screw Second Punches Available in the Market

When selecting a screw second punch, understanding the various types available in the market is crucial. There are typically three main categories: manual, pneumatic, and electric. Manual screw second punches are favored for their portability and ease of use, making them ideal for smaller projects. Pneumatic options, powered by compressed air, offer speed and efficiency but may require a more extensive setup. Electric screw second punches are versatile and suitable for high-volume tasks, ensuring consistent performance and reducing labor fatigue.

Tip: Before making a purchase, assess your specific needs by determining the frequency of use and the scale of your projects. This can vastly influence the type of punch that will serve you best.

Additionally, consider the material compatibility of your punch. Different screw second punches are designed for various materials, such as metal, plastic, or wood. Using the correct tool will not only enhance performance but will also extend the life of the punch.

Tip: Always check the manufacturer's specifications and reviews to gauge the durability and efficiency of the punch you’re considering. This can help you avoid costly mistakes and ensure you invest in the right tool for your requirements.

Key Technical Specifications to Consider When Choosing a Screw Second Punch

When selecting a screw second punch, understanding its key technical specifications is crucial for optimal performance. One of the most important factors to consider is the material composition of the punch. According to a recent industry report by TechMarketInsights, high-carbon steel and tungsten carbide are the most preferred materials due to their durability and ability to withstand the stresses of repetitive use. These materials exhibit a greater resistance to wear, resulting in longer lifespans and reduced maintenance costs.

Another vital specification is the punch size and geometry, which directly impacts the precision and effectiveness of the punch. A study by Precision Tools Research indicated that punches with specific geometrical profiles can significantly enhance the punching efficiency by up to 30% compared to standard designs. This improvement is essential for industries requiring high accuracy in component fabrication, such as automotive and aerospace sectors.

Lastly, the punch's compatibility with existing machinery cannot be overlooked. Ensuring that the second punch aligns with your equipment's specifications is critical for achieving optimal operational efficiency. A misalignment can lead to costly downtimes and reduce overall productivity, highlighting the importance of consulting detailed technical guides and manufacturer specifications before making a purchase.

Step-by-Step Guide: How to Select the Right Screw Second Punch for Your Project

When selecting the right screw second punch for your project, it’s essential to consider the specific requirements of your application. Factors such as material type, thickness, and the intended use of the punch will significantly influence your decision. According to a report by the Industrial Fasteners Institute, using the correct punch can increase efficiency and enhance the durability of your fastening solutions. A punch that matches the material properties will reduce wear and tear, ensuring consistent performance over time.

**Tip:** Always review the manufacturer’s specifications for the screw second punch. Look for details on the material compatibility and recommended uses to avoid potential failures during operation.

Moreover, understanding the size and design is crucial. The American National Standards Institute (ANSI) provides guidelines on punch sizes and specifications that can help you make an informed choice. Choosing the right size not only facilitates easier installation but also contributes to better alignment and stability during usage.

**Tip:** Consider investing in adjustable or interchangeable punches if your projects vary in requirements. This flexibility can save time and costs in the long run.

The Ultimate Guide to Choosing the Best Screw Second Punch for Your Needs

| Type of Punch | Material | Size (mm) | Usage | Price Range ($) |

|---|---|---|---|---|

| Manual Punch | Steel | 6, 8, 10 | Small Projects | 15 - 25 |

| Electric Punch | Aluminum | 10, 12, 14 | Medium to Large Projects | 100 - 200 |

| Pneumatic Punch | Carbon Steel | 6, 8, 12 | High Volume Production | 200 - 500 |

| Hydraulic Punch | Stainless Steel | 10, 14, 20 | Heavy Duty | 500 - 1500 |

Common Mistakes to Avoid When Purchasing a Screw Second Punch

When purchasing a screw second punch, one of the most common mistakes buyers make is failing to consider their specific requirements. Many assume that all screw second punches are created equal, resulting in choosing a model that doesn’t fit their needs. Always evaluate the material you’ll be working with, the thickness of the material, and the volume of production you expect. A punch that excels in one area may falter in another, so it's crucial to understand your unique requirements before making a decision.

Another frequent oversight is neglecting to review the quality of the punch itself. Not all brands offer the same level of durability and performance. Investing in a low-quality tool can lead to frequent replacements and inefficiencies in your workflow. Check for warranties, customer reviews, and the reputation of the manufacturer. A reliable screw second punch will not only enhance productivity but also ensure consistent results, making your investment worthwhile in the long run.

Maintenance Tips to Extend the Life of Your Screw Second Punch

When it comes to ensuring the longevity of your screw second punch, proper maintenance is critical. According to a report by the Precision Tool Institute, regular maintenance can extend tool life by as much as 30%. This emphasizes the importance of implementing a strict maintenance schedule that includes regular inspections and cleaning. Consistent checks for wear and tear can help identify issues before they escalate, saving both time and costs associated with premature replacements.

In addition to regular inspections, proper lubrication is essential for optimal performance. The Industrial Maintenance Association suggests that using the right type of lubricant can reduce friction and wear, leading to a more efficient operation. For screw second punches, it’s recommended to use synthetic oils specifically formulated for high-pressure applications. Regularly applying lubricant according to manufacturer guidelines can effectively extend the life of your tools, resulting in better precision and less downtime in production. Engaging in these proactive maintenance practices not only improves tool performance but also enhances overall productivity in the workplace.